Solution without compromise

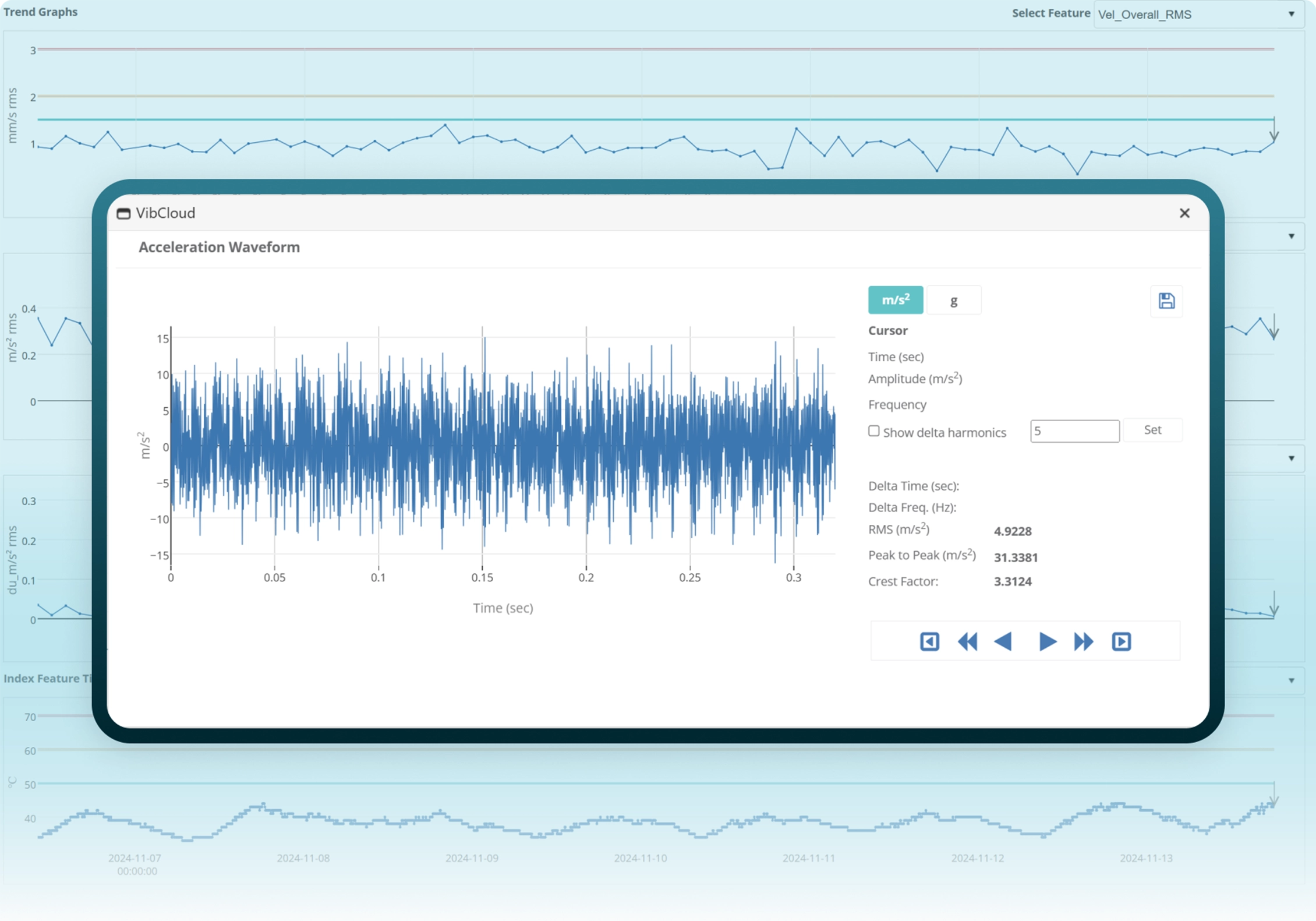

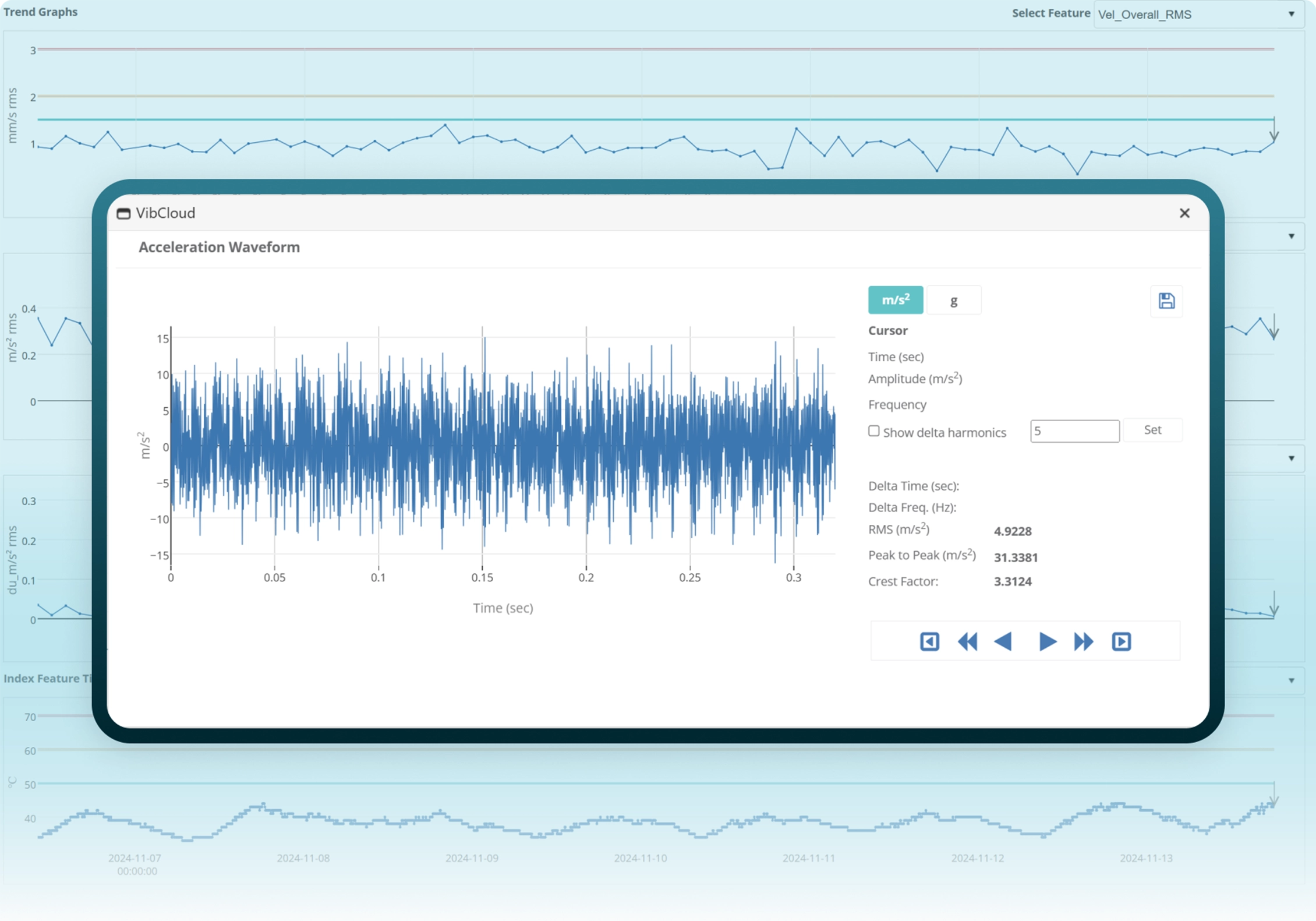

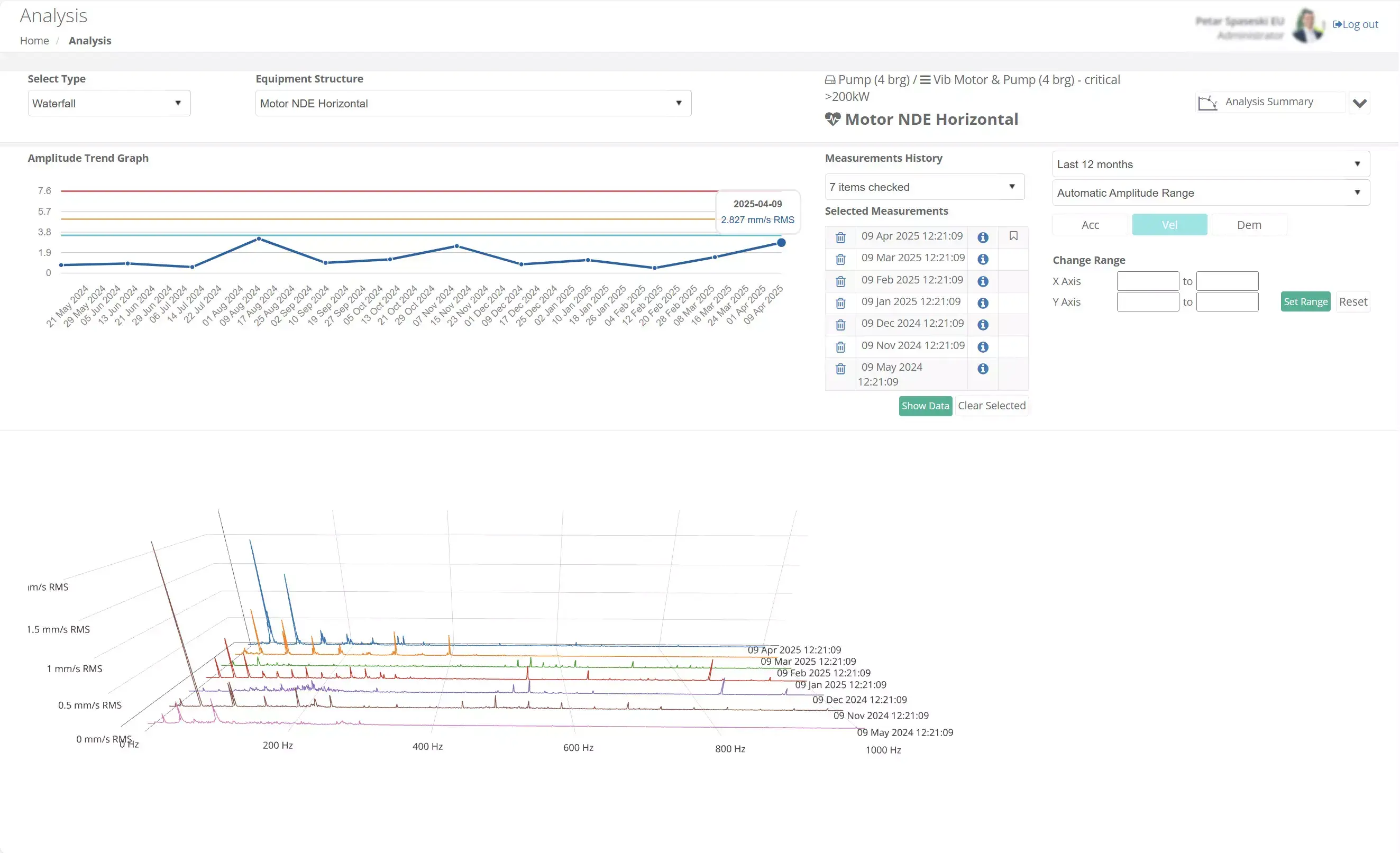

The most powerful, flexible, and affordable vibration data collection

and

analysis solution on the market, designed for ease and efficiency.

The most powerful, flexible, and affordable vibration data collection

and

analysis solution on the market, designed for ease and efficiency.

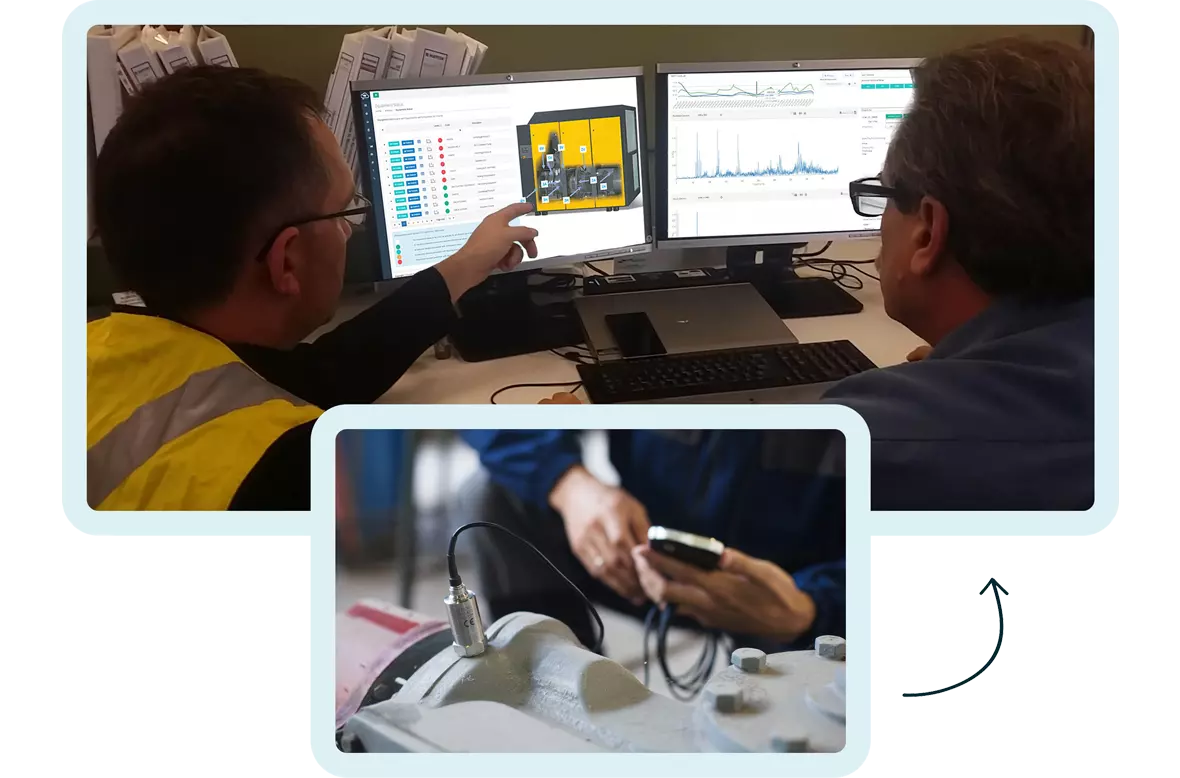

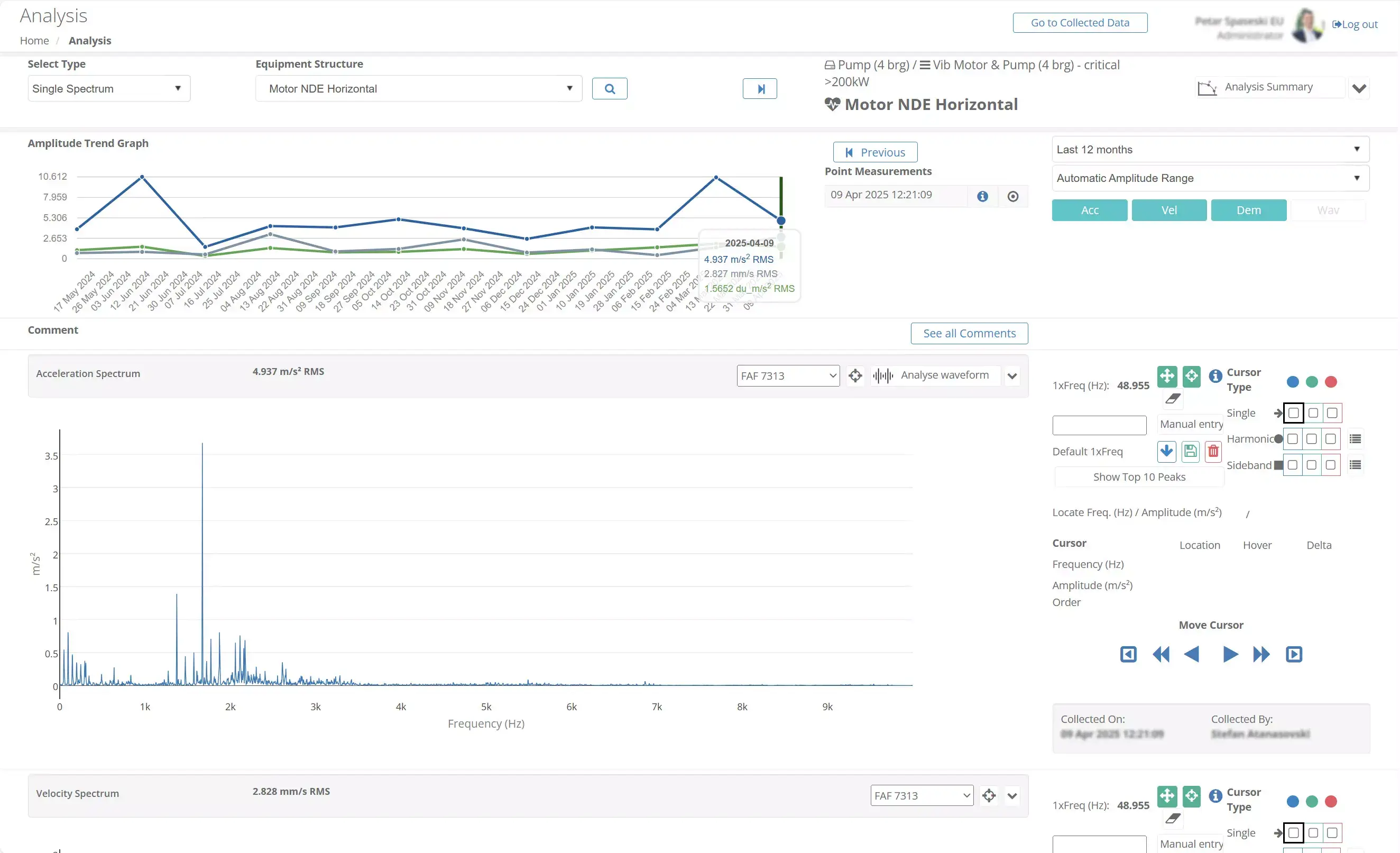

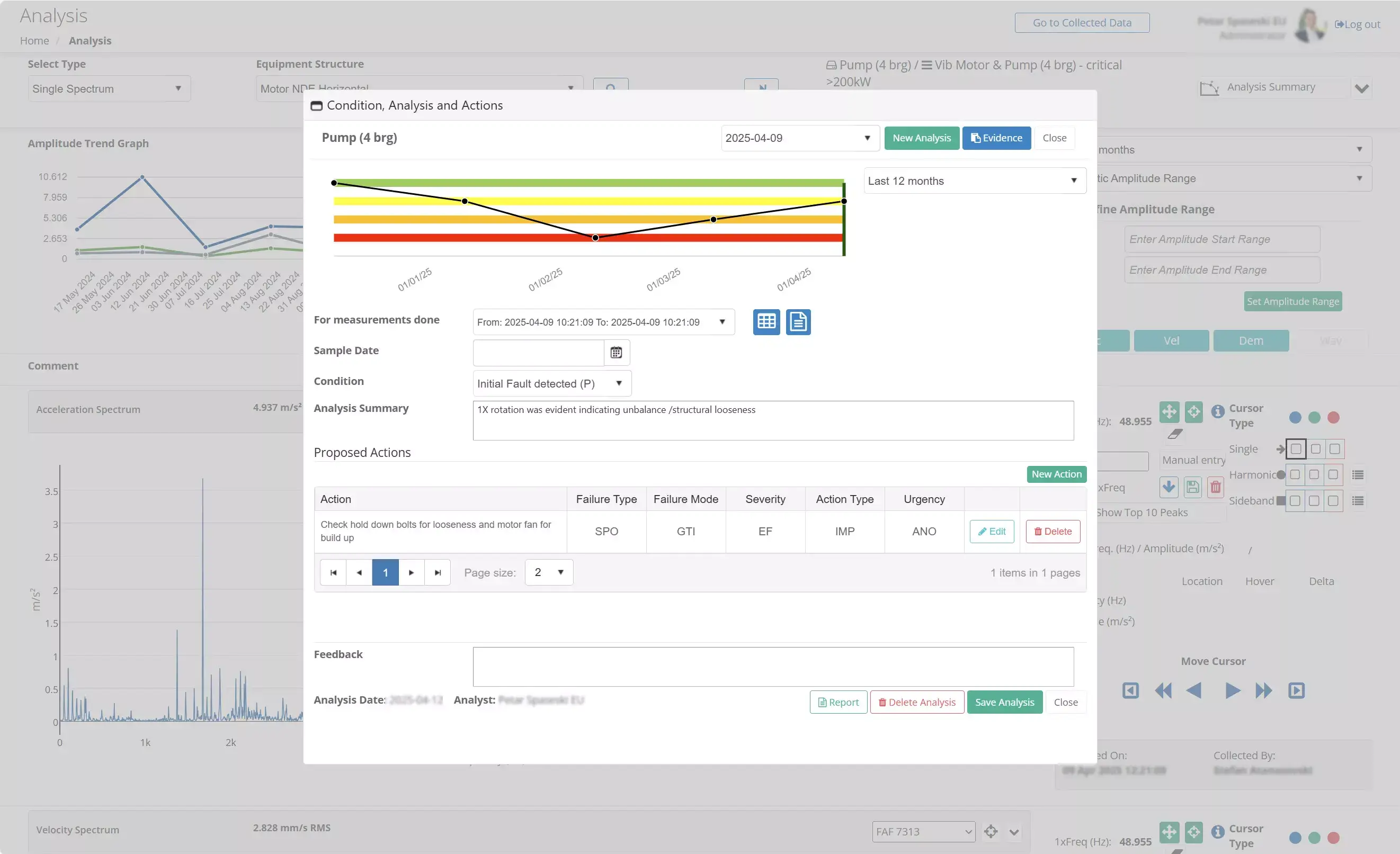

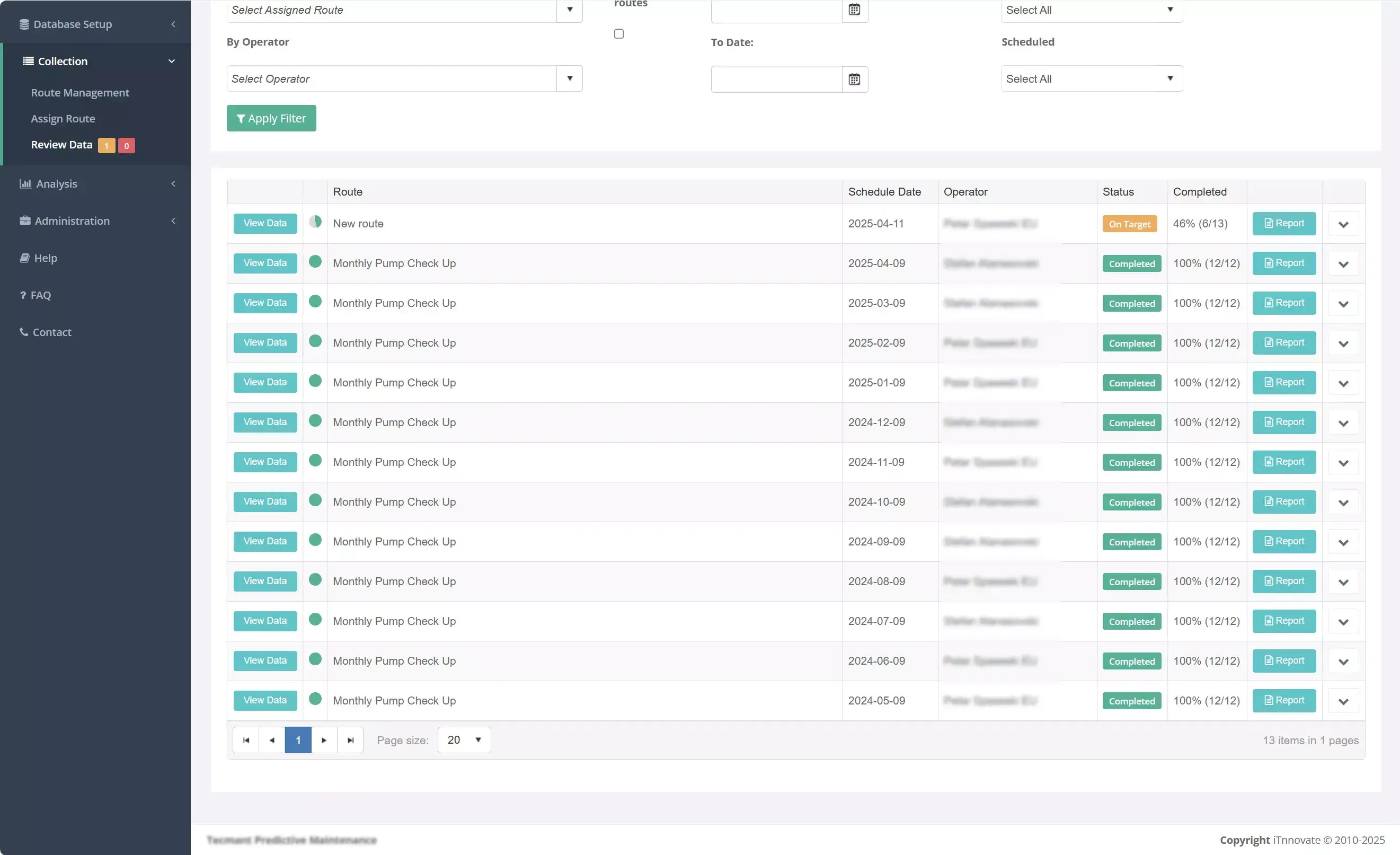

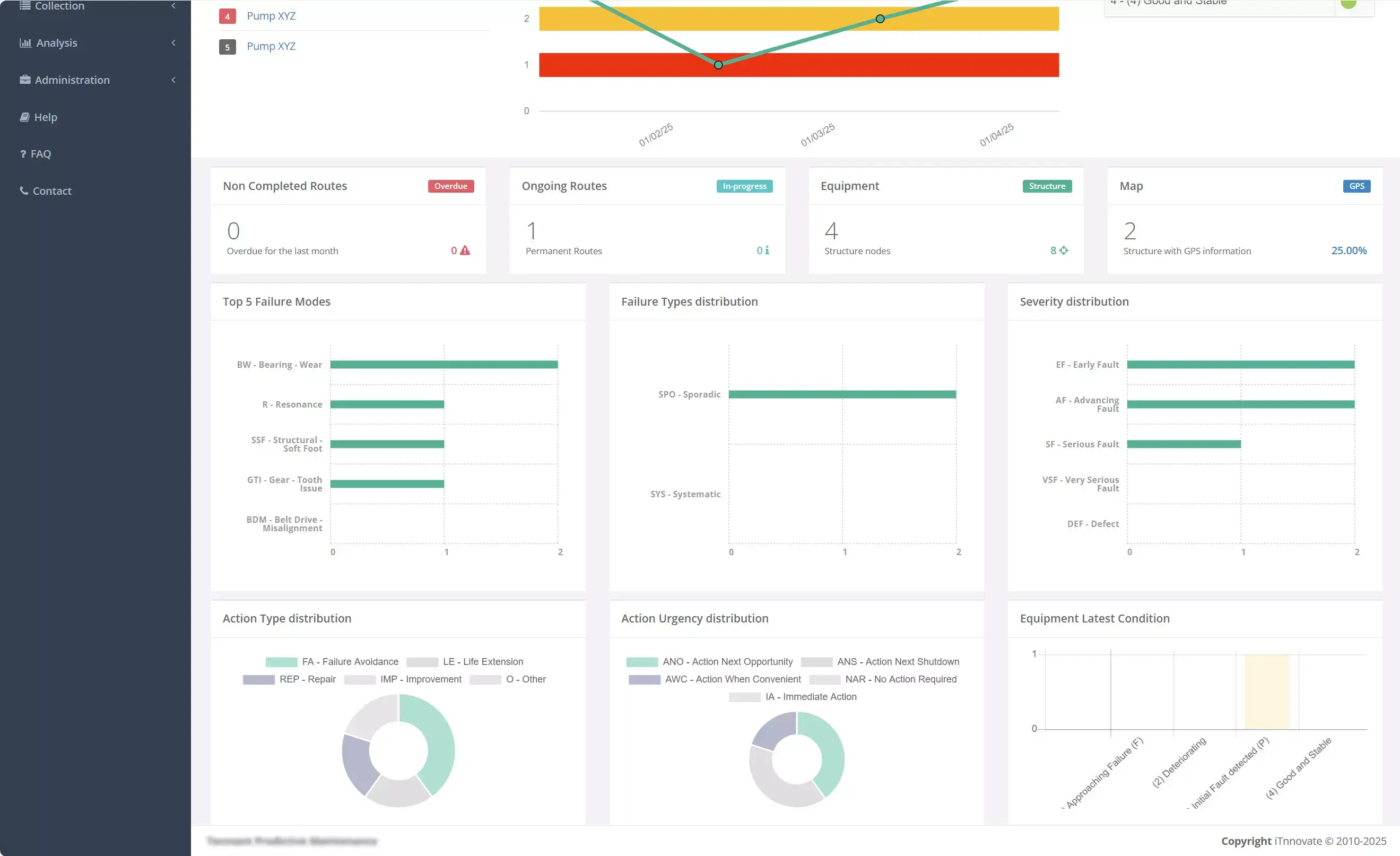

Equip your team with the tools to collect and analyse vibration data efficiently, ensuring smooth operations and reliable results.

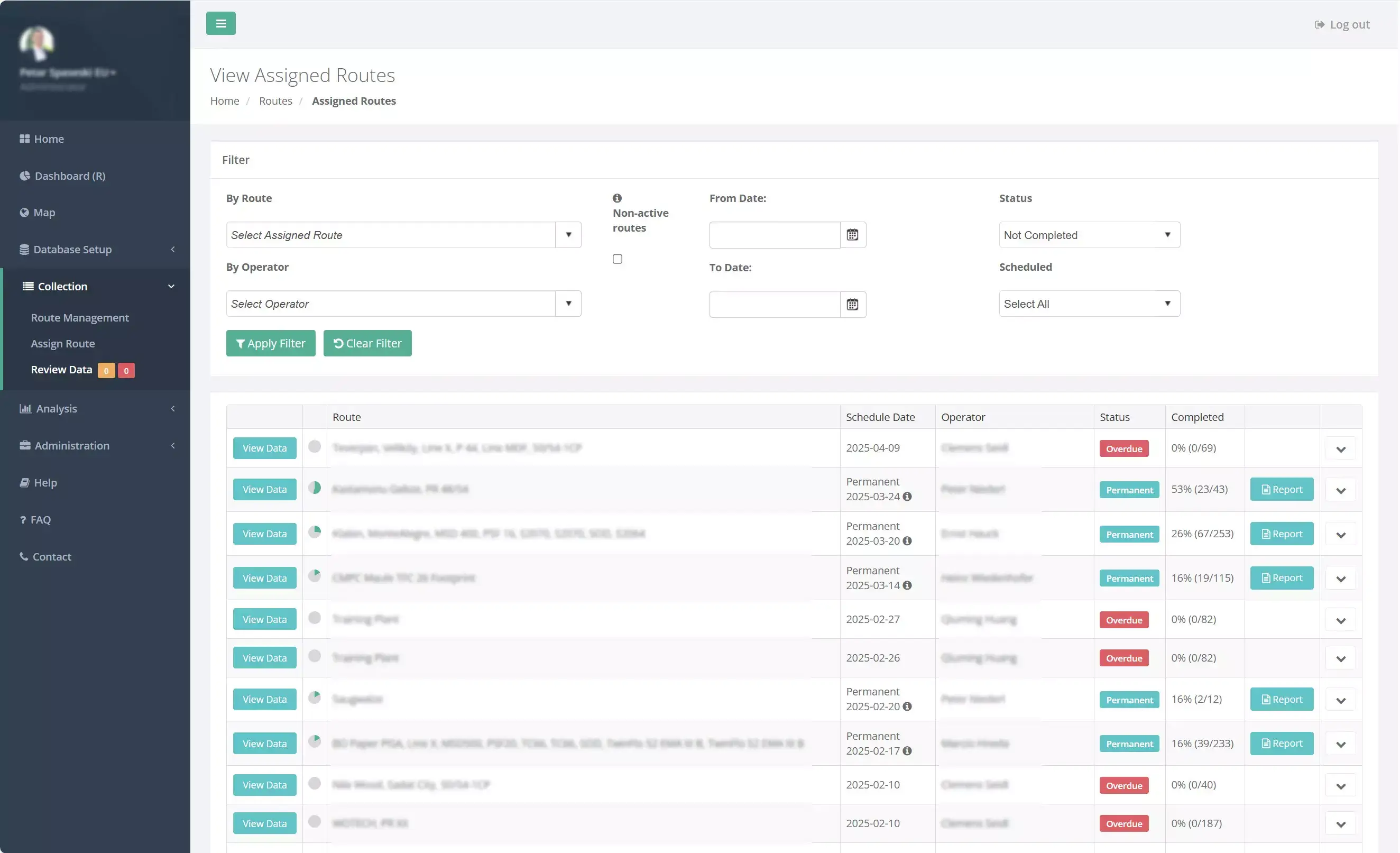

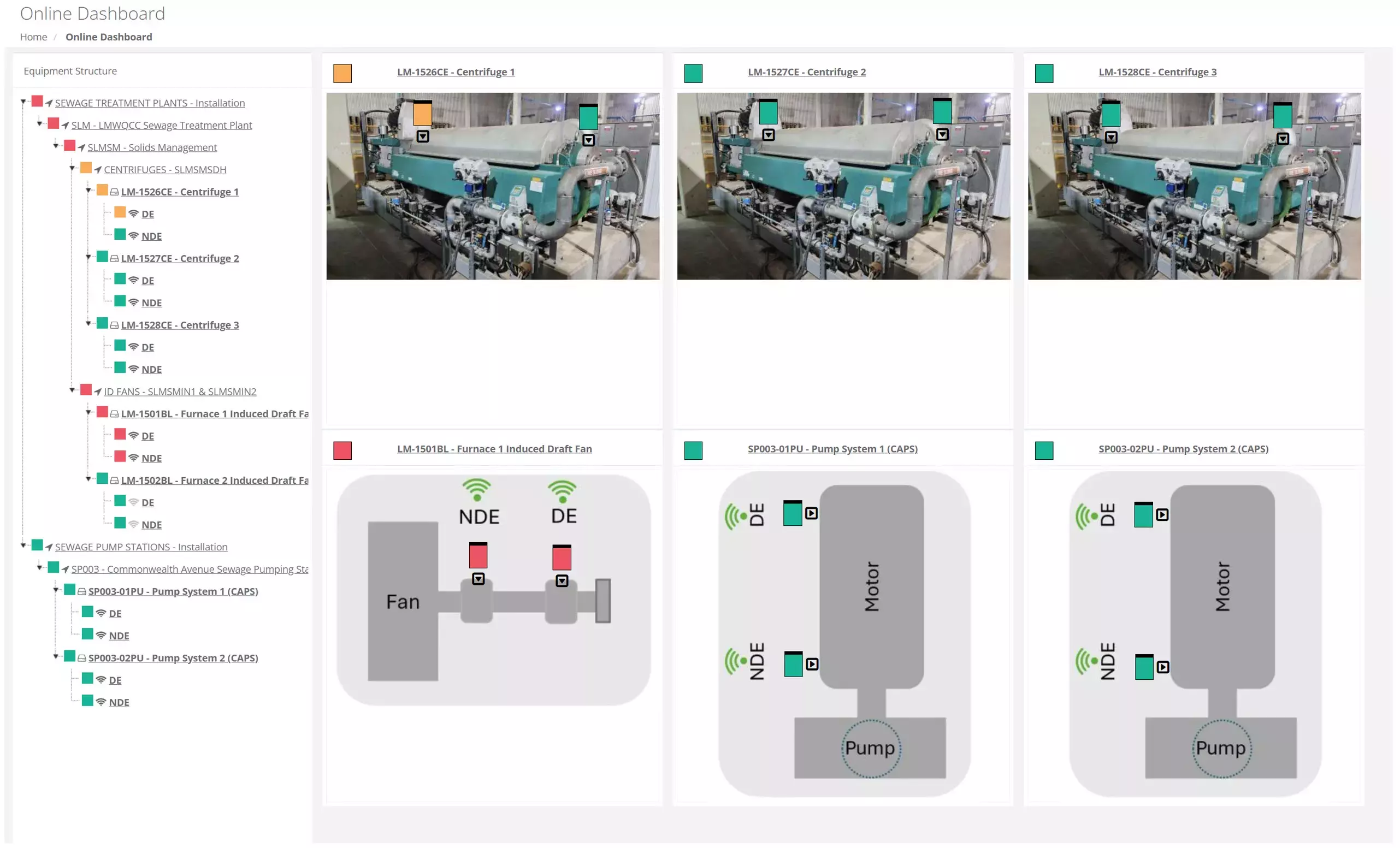

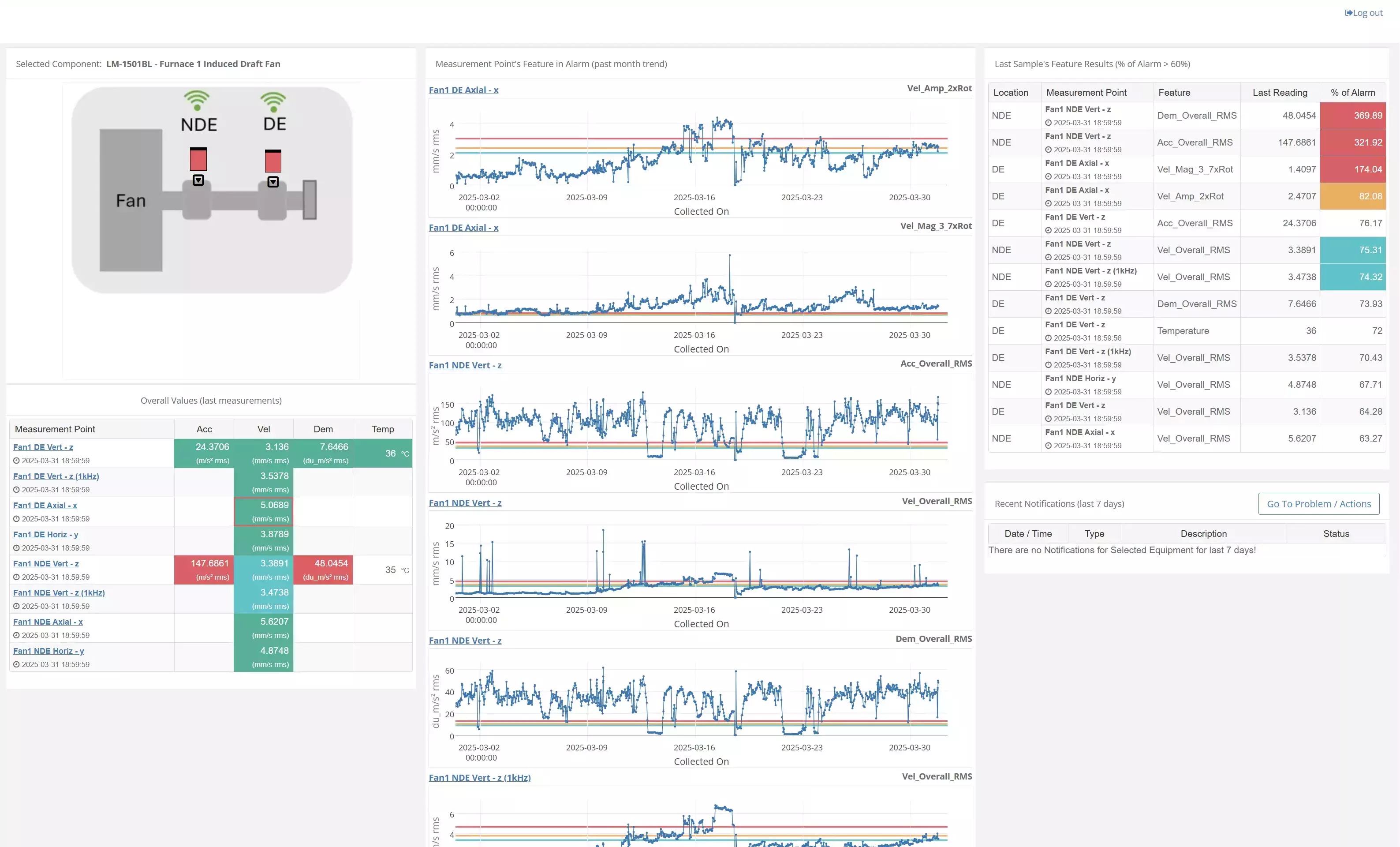

One solution for both route-based and online monitoring.

Use anywhere, anytime—just a browser needed.

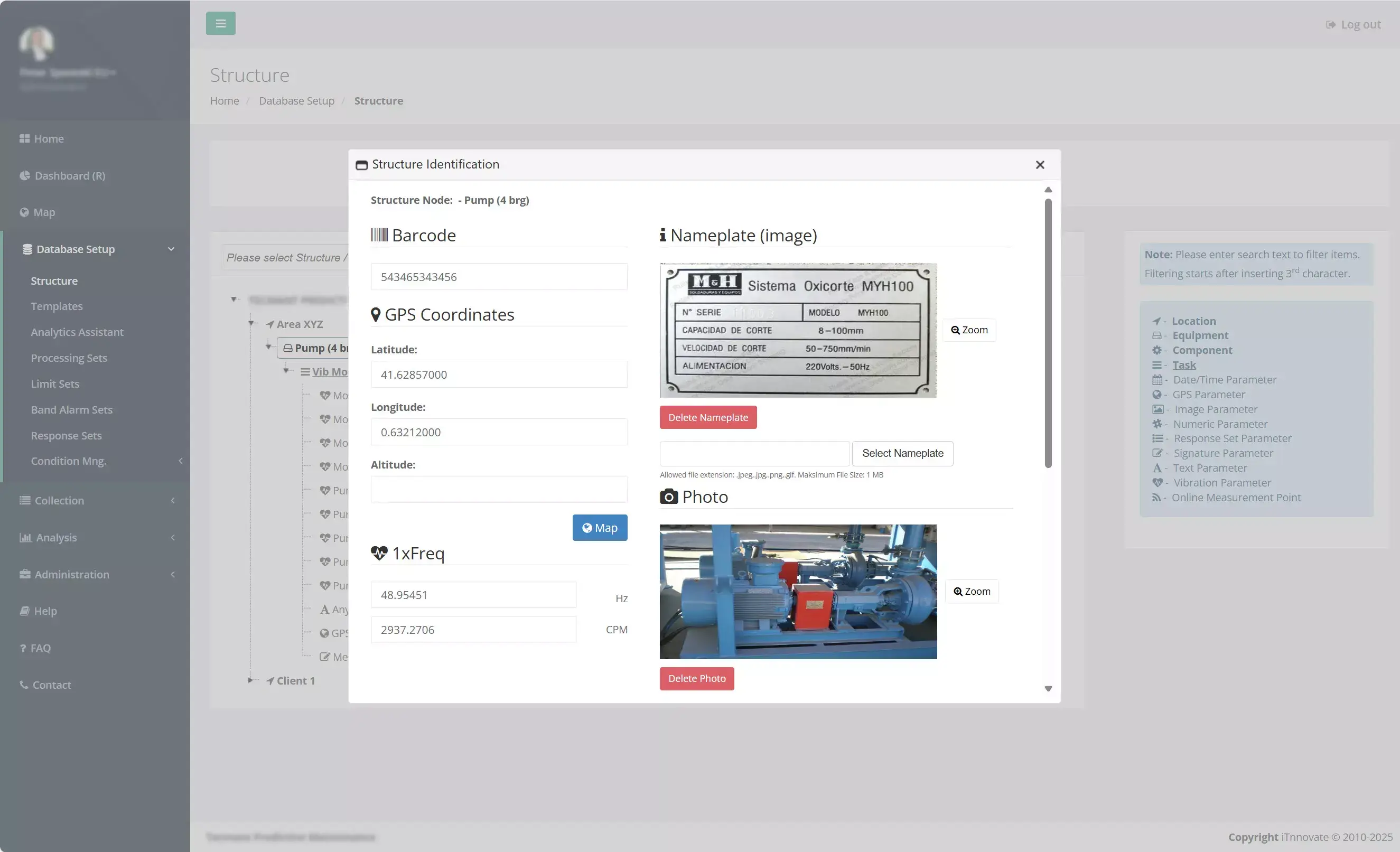

Cloud database that maintains an asset hierarchy and stores all essential equipment information.

Set parameters, routes, and frequencies with ease. Configurable notifications.

Manage users and permissions effectively.

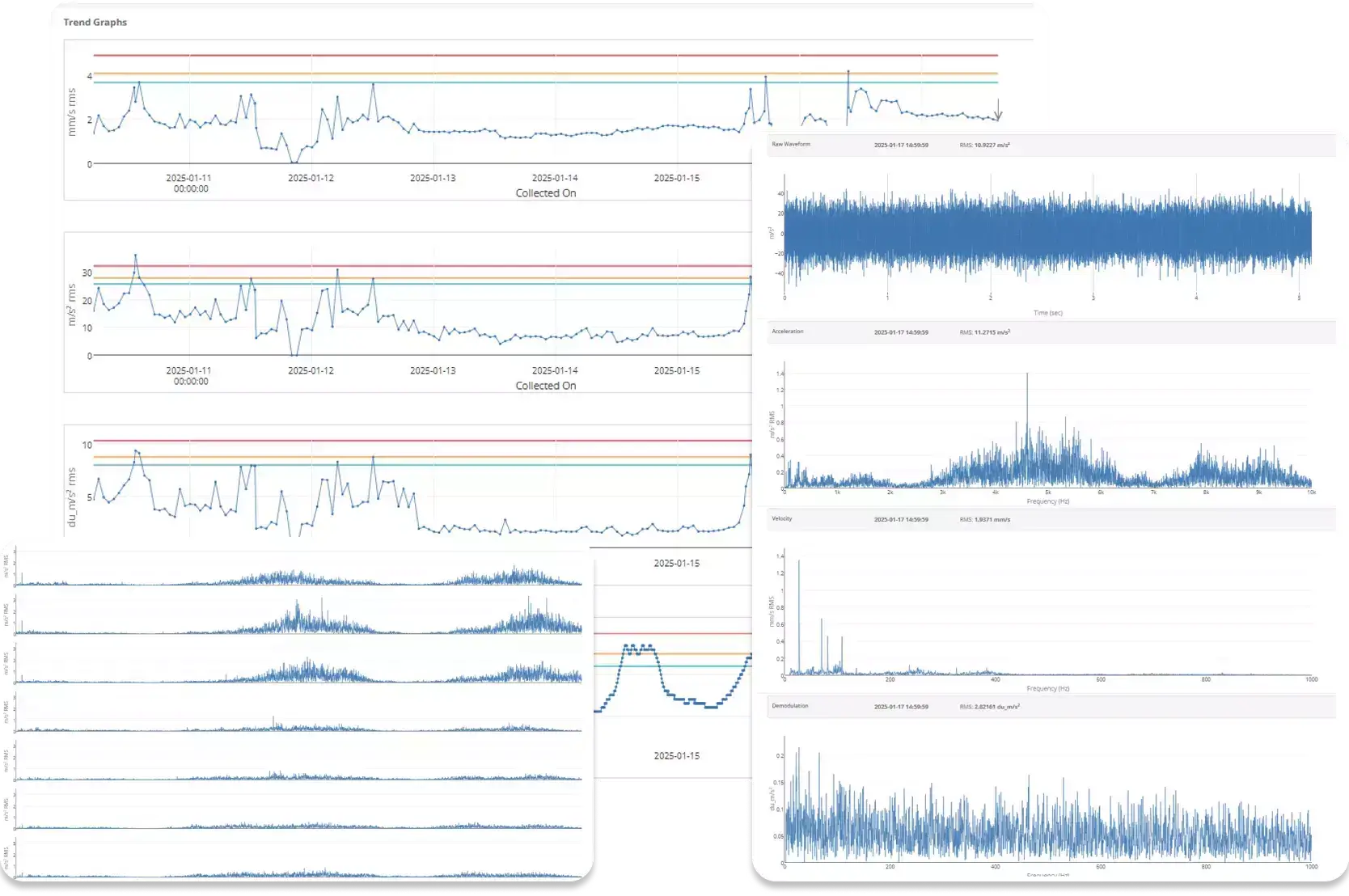

Dashboards, reports, and insights at your fingertips. AI Ready for advanced models.

VibCloud empowers every team member—from managers to analysts—to make better, faster maintenance decisions with actionable insights.

Start monitoring vibration today to prevent downtime and boost

performance.

Choose a plan that fits your needs and keep your operations running smoothly.