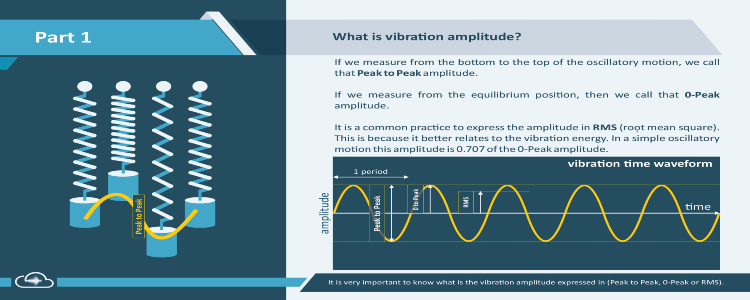

Vibration Analysis 101

We have developed a simple guide to understand vibration and help you learn the basics of vibration analysis. What is vibration, waveform and spectrum; How is complex vibration transformed in a simple spectrum, are some of the questions answered.

Download →